close

Choose Your Site

Global

Social Media

| Availability: | |

|---|---|

| Quantity: | |

Characteristic:

●Controllable temperature and flow, to provide a thermostatic environment

●Equipped with a inside cooling bath for direct cooling materials inside

●Digital display of temperature makes the temperature setting simple and flexibly Efficient and secure temperature conversion

●Safe in operation, easy to move around with casters with lock

●A variety of fault alarm (over temperature alarm, sensor alarm, high pressure alarm, compressor overheat alarm, liquid level alarm)

●Closed cycle pipeline design to prevent circulating water from pollution and extend the lifetime of circulation liquid.

●Circulating system adopts SUS304 stainless steel material and macromole anti-corrosion material, which can prevent rust,corrosion and low temperature liquid pollution

Parameter:

| Cooled Water Circulation System | ||||||||

| Model | TWL-25MF | TWL-50MF | TWL-70MF | TWL-100MF | TWL-150MF | TWL-260MF | TWL-300MF | TWL-500MF |

| Outer Size | D80xW45xH130 | D90Xw50xH130 | D110xW60xH176 | D120xW60xH180 | D120xW75xH180 | D120xW80xH180 | D150xW85xH180 | D220xW110xH180 |

| Medium Temperature Range | 5℃~35℃ | |||||||

| Temperature Control | High-precision controller to control the outlet temperature (can record set temperature, measured temperature data and curve) | |||||||

| Fluctuation | A: 0.5°C/B: 1.0°C/C: 2.0°C (under no load or constant load) | |||||||

| Volume Control Type | Manual | |||||||

| Cooling Capacity | 2.5KW | 5 KW | 7 KW | 10 KW | 15 KW | 25 KW | 30KW | 50 KW |

| 2150Kcal/h | 4300Kcal/h | 6020Kcal/h | 8600Kcal/h | 12900Kcal/h | 21500Kcal/h | 25800 Kcal/h | 43000 Kcal/h | |

| Water Tank Volume | 20L | 35L | 40L | 50L | 60L | 100L | 200L | 300L |

| Flow output | 2~20L/min | 3~25L/min | 5~40L/min | 5~55L/min | 5~70L/min | 110L/min | 200L/min | 250L/min |

| Working Noise | ≤72 dB(A) | |||||||

| Working Power | ~1.5KW | ~1.9KW | ~2.65KW | ~3.8KW | ~5.35KW | ~8.6KW | ~11.3KW | ~17.9KW |

| QTY of Compressor | 1 set | 1 set / 2 set | ||||||

| Cooling Method | Single-stage refrigeration / multi-machine parallel | |||||||

| Compressor | "Mitsubishi" / "Copeland" | |||||||

| Refrigerant | R22 (optional R407C DuPont environmentally friendly refrigerant) | |||||||

| N.W. | 136kg | 175kg | 210kg | 265kg | 320kg | 350kg | 410kg | 530kg |

| Cooling Type | Air-cooled (optional water-cooled plate replacement, the cost remains unchanged) | |||||||

| Heater | In-Line/Submerged | |||||||

| Controller | HLS-U760W | |||||||

| Connection Size | DN15 | DN20 | DN20 | DN20 | DN25 | DN32 | DN40 | DN40 |

| Power Supply | AC220V 50HZ( optional AC240V 60HZ) | AC380V 50HZ(optional AC440V 60HZ) | ||||||

| Safety Device | 1. Compressor pressure protection | |||||||

| 2. Phase sequence/phase loss protection | ||||||||

| 3. Mechanical over-temperature protection | ||||||||

| 4. Electronic over-temperature protection | ||||||||

| 5. Water flow protection device | ||||||||

| 6. Liquid level protection device | ||||||||

| 7. Antifreeze protection device | ||||||||

| Explanation | Take TPWL-25LAM as an example, TPWL is a precision cooling water system produced by Harris ; the number 25 means the cooling capacity | |||||||

| is 2.5KW; the letter L means the standard low temperature type (the high temperature type is H); the letter A is the water | ||||||||

| temperature control fluctuation The temperature is 0.5℃; the letter M indicates that the water flow is manually adjusted. | ||||||||

Application Areas:

Chemical fiber industry:

Freeze relatively dry air and ensure product quality.

Vacuum coating:

It can be used to control the temperature of vacuum coating machines to ensure high quality of plated parts.

Plastic industry:

Accurately control the temperature of each plastic processing, shorten the plastic cycle, and ensure stable quality.

Electroplating industry:

It can control the temperature of electroplating and increase smoothness and density.

Food industry:

Used for high-speed cooling after food processing, so that food can quickly adapt to packaging requirements, in addition to controlling the temperature of fermented food, etc.

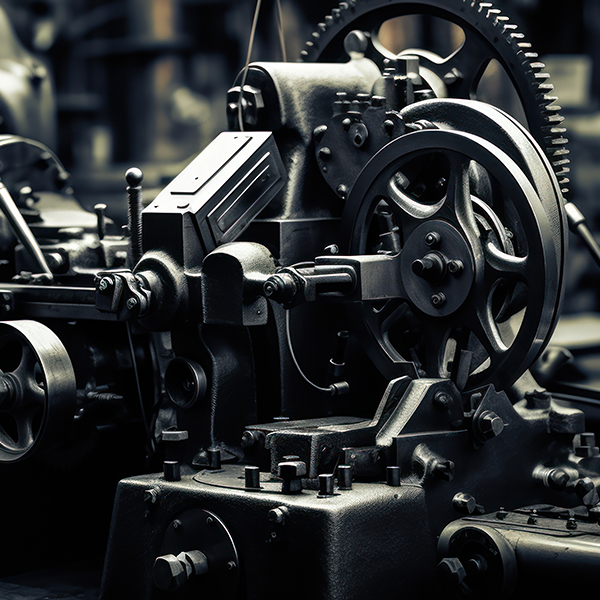

Mechanical industry:

Used to control the pressure oil temperature of the hydraulic system, extend service life, improve mechanical lubrication efficiency, and reduce wear.

Construction industry:

Can supply concrete for chilled water, so that the structure of concrete is more in line with construction requirements, effectively enhancing its hardness and toughness.

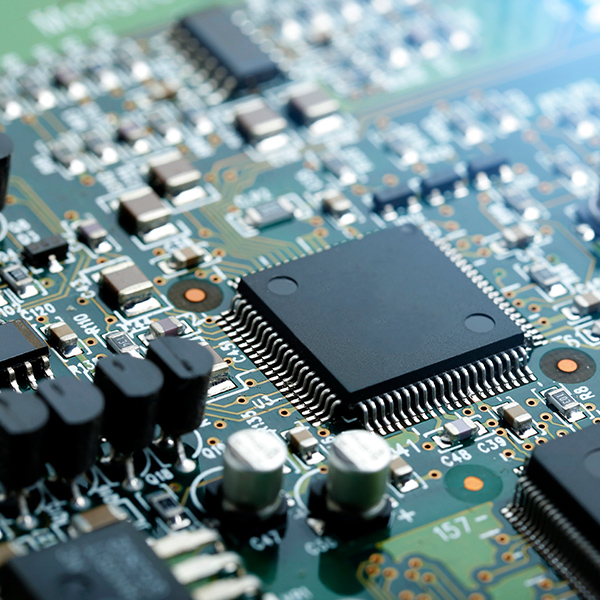

Electronic industry:

industrial chillers can stabilize the molecular structure of electronic components on the growth line, improve the pass rate, and are mostly used in the ultrasonic cleaning industry to effectively prevent the volatilization of expensive cleaning agents from causing harm to people.